Premium Wholesale Faux Fur Rugs | GPT-4 Turbo Style

The global faux fur rugs wholesale industry is expanding rapidly, fuelled by eco-conscious consumer demand, sophisticated manufacturing, and the evolution of interior design aesthetics. This comprehensive guide delves into the technical and commercial landscape of faux fur rugs—comparing leading products, detailing manufacturing processes, discussing real-world usage, and providing actionable industry data.

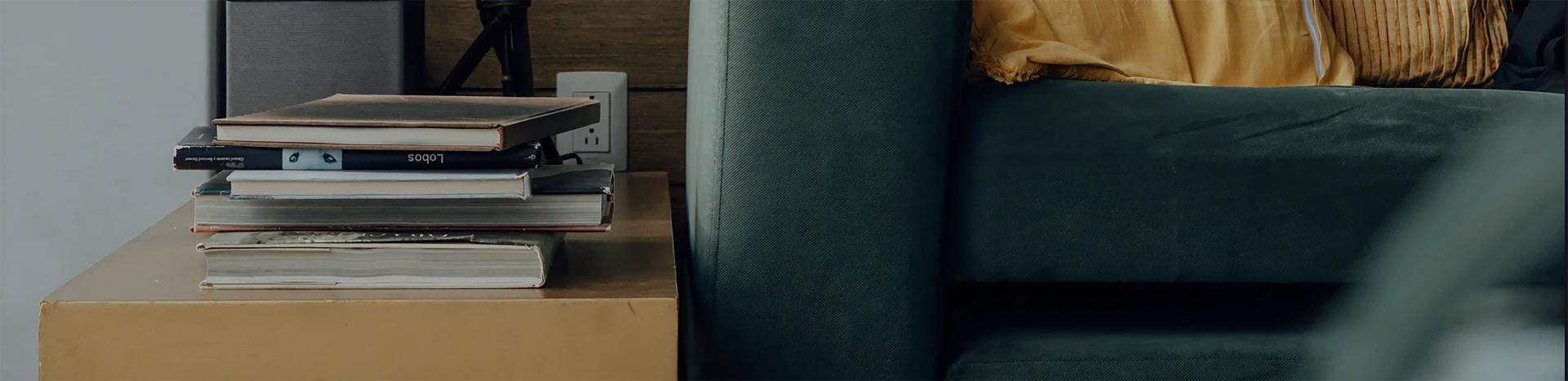

Ultra-soft pile and texture of faux fur rugs for sale enhance any modern interior.

Industry Trends: Faux Fur Rugs Wholesale Market Overview

Over the past decade, faux fur rugs wholesale has transitioned from a niche offering to a mainstream, highly competitive market. According to Grand View Research, the global faux fur market size was valued at USD 248.9 million in 2023, projected to grow at a CAGR of 6.1% from 2024 to 2030.

- Eco-Friendly Appeal: Advancements in polyester/acrylic fiber blending have enhanced the sustainability and tactile comfort of fake sheepskin rug products.

- Customization & Branding: Factories offer extensive color, pattern, and shape customization, critical for contract and hospitality applications.

- Digitalization: Online B2B/B2C models and virtual design allow buyers to buy faux fur rug in bulk with full transparency.

Emerging colorways and forms of fake sheepskin rug dominate the market.

Technical Parameters: What Sets Wholesale Faux Fur Rugs Apart

1. Fiber Materials & Structure

- Main Materials: 100% Polypropylene, Microfiber Polyester, or Blended Acrylic

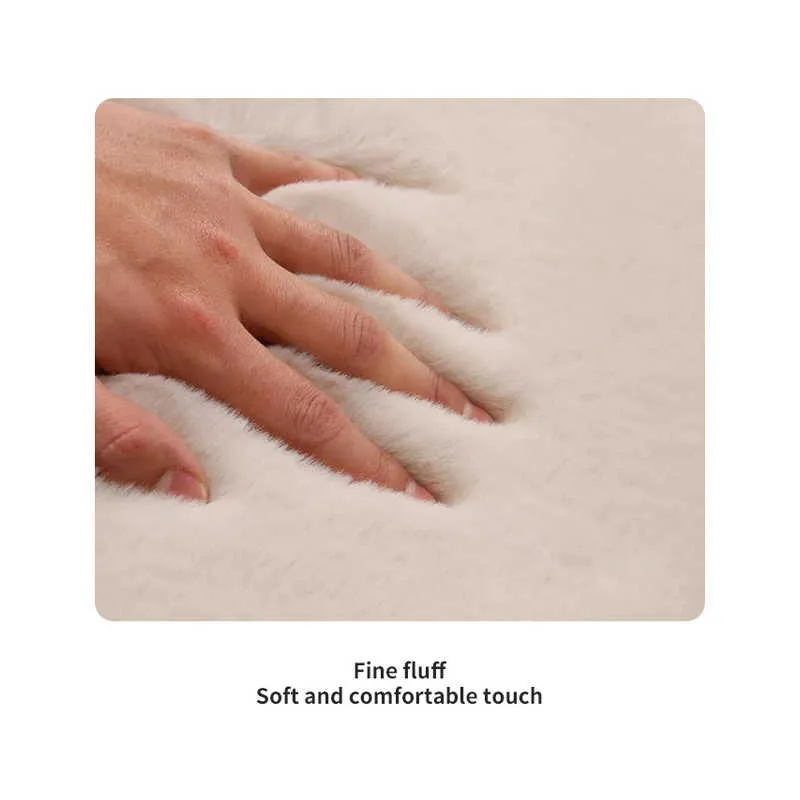

- Ultra-fine denier fibers (often < 2 denier) replicate the softness of natural fur.

- Backing: Non-woven polyester with anti-skid TPR/latex dots

2. Pile Height & Density

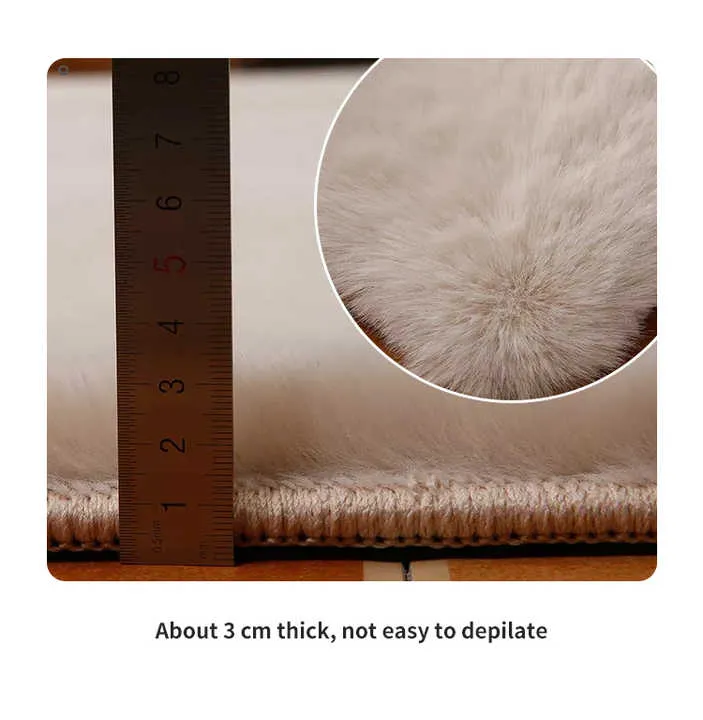

- Pile Height: 25mm~35mm (typ.), up to 50mm custom

- Density: 1400–2200 GSM (grams/sq. meter)

- Stitching: Machine-stitched with ISO 9001/14001 compliance

3. Key Performance Indices

- Color Fastness: ≥ 4 (ISO 105-C06)

- Shedding Rate: ≤ 1% (after 10k cycles/ISO 12945-2)

- Anti-slip: TPR base passes ASTM D3676

- Lifespan: 5–10 years under normal commercial/home use

Standard Product Specifications Table: Faux Fur Rugs Wholesale vs. the Market

| Parameter | Wholesale Custom Rug Fluffy Carpet Faux Rabbit Fur | Typical Faux Animal Hide Rug | Cheap Faux Fur Rugs (Low-End) |

|---|---|---|---|

| Main Fiber | Microfiber Polyester (Faux Rabbit Fur) | Poly/Acrylic Blend | Low Density Polypropylene |

| Pile Height | 30 mm | 18-25 mm | 10-17 mm |

| Density (GSM) | 2000 GSM | 1400-1800 GSM | 900-1200 GSM |

| Base/Backing | TPR Anti-skid | Latex/PVC | Non-woven/Low-adhesion |

| Color Fastness | ≥ 4.5 (ISO 105) | 3.5-4 | 2.5-3 |

| Shedding Rate | <1% | <2% | 4%-10% |

| Washability | Machine Washable | Hand-wash recommended | Not recommended |

| Certification | ISO 9001, OEKO-TEX 100 | Vendor-specific | None/Basic |

| Lifespan (yrs) | ≥7 | 3-5 | 1-2 |

Manufacturing Process: From Fiber to Ultra-Soft Rug

State-of-the-art production ensures that faux fur rugs wholesale products closely rival natural fur in tactile quality and aesthetic realism. Below is a visual/stepwise breakdown:

Modern production line for faux fur rugs wholesale and custom fabrication.

1. Fiber Preparation

- Blending of polyester microfibers (e.g., 1.5D × 38mm) for softness and resilience.

- Coloring via high-pressure dyeing (ISO 105-compliant)

2. Weaving/Knitting

- Automated jacquard looms form high-pile fabrics (CNC-assisted precision).

3. Laminating & Backing

- TPR or latex compound coating for anti-skid, machine placement for uniformity.

Inspection & Standards

- Mechanical & Visual Testing: Pile integrity, color consistency, shedding simulation (up to 10,000 abrasion cycles).

- Compliance: ISO 9001, OEKO-TEX 100, ASTM F2057 (anti-skid, safety), and EN 71-3 for children’s safety.

Data Visualization: Market & Product Comparisons

Relative Density & Shedding Rates (Compared)

Product Performance Split (Pie Chart: Key Value Parameters)

Long-Term Performance (Wash Cycles vs. Lifespan)

Supplier Comparison: Leading Faux Fur Rugs Wholesale Solutions

| Key Features | Wholesale Custom Rug Fluffy Carpet | Competitor A (China) |

Competitor B (Turkey) |

|---|---|---|---|

| Fiber Innovation | Ultra-Fine Faux Rabbit Fur (1.5D/38mm) | Polypropylene Mix (2.5-3.2D) | Artificial Wool (blended, 2.2D) |

| Pile Height/Softness | 30mm, Luxury Dense | 18mm, Standard | 20mm Curly Pile |

| Certifications | ISO 9001, OEKO-TEX, EN71-3 | OEKO-TEX | ISO 14001 |

| MOQ / Customization | 25 pcs / Infinite Color/Pattern | 100 pcs / Limited | 50 pcs / Medium |

| Price Range | $6.8~$12.5/m² | $8.9~$14/m² | $8.2~$13.7/m² |

| Typical Lead Time | 10–18 days | 15–30 days | 18–28 days |

| Warranty | 3 Years (“Total Care”) | 1 Year | 1-2 Years |

Customization Solution: Get Your Faux Fur Rugs Wholesale Tailored

- Size & Shape: Any dimensions up to 4m × 20m; round, oval, square, freeform.

- Color & Pattern: Pantone matching, digital photo printing, gradient color effects.

- Backing Type: Choose TPR, latex, felt or composite for site-specific requirements.

- Edge Finishing: Overlocked, hidden seam, stitched border (for commercial traffic tolerance).

- Branding/Logo: Hot stamping or jacquard-knitted for faux animal hide rug & luxury venues.

- Compliance: Can meet EN 13501 (fire/fire-retardant), OEKO-TEX, and REACH upon request.

Application Scenarios: From Living Spaces to Commercial Landmarks

- Luxury bedrooms, nurseries, and living rooms seeking high-pile comfort.

- Custom faux animal hide rugs elevate designer interiors (e.g., Scandinavian, Mid-century).

E.g., HILTON, LUSHHOME chain boutique installations (2023–2024)

- Easy-to-clean fake sheepskin rug placement for zones with high spill risk.

- Can withstand 10,000+ foot traffic cycles (ISO abrasion test).

Case study: CELEBCAFE, Italy (2024), chose wash-and-dry faux fur mats for their anti-slip performance.

- OEKO-TEX certified, hypoallergenic, compliant with EN 71-3 chemical safety.

- Easy-spot clean for playrooms and pet zones.

E.g. ALL4KIDS XYX nursery, 2k㎡ project installation (2023)

- Pop-up stores seeking affordable branding with cheap faux fur rugs (logo-matting).

- Implemented by H&M, Japan, for 2023 Winter Campaign visual merchandising.

Proven in stone, chemical industries for dust-free soft zones.

Real-life application: Buy faux fur rug for modern hospitality interiors.

Customer Experience & Case Snapshots

- Global Distribution Network: Shipped to 42 countries (2023–2024), incl. USA, UK, UAE, Australia.

- Repeat Client Rate: 36% of wholesale clients reorder within 18 months—a reference point for reliability.

- Industry Adoption: Used by 10+ top-tier contract interior brands as an alternative to real animal hides.

- Customer Feedback: “Luxurious feel, minimal shedding, better than real fur for allergy-prone clients. Our go-to for commercial accent rugs.” — L.D., Sweden, 2023.

Frequently Asked Questions: Technical & Buyer Concerns (Expert FAQ)

1. What is the typical pile height for faux fur rugs wholesale and why does it matter?

Standard pile height ranges from 25mm–35mm for plushness. Higher pile delivers greater comfort and a more realistic “fur” effect but increases production cost and care sensitivity.

2. How is shedding rate assessed, and what value is acceptable?

Shedding is measured post-abrasion (ISO 12945-2), with quality rugs showing ≤1%. Higher rates (4–10%) typically occur in low-end cheap faux fur rugs due to loose fibers and inferior weave.

3. What base/backing types are available in wholesale faux animal hide rug?

Most offer TPR (thermoplastic rubber, anti-skid, machine-washable), latex (strong grip, less washable), or felt (budget) for various applications including wet, high-traffic, or premium use cases.

4. Which certifications ensure safety and quality?

Look for ISO 9001 (QA management), OEKO-TEX 100 (chemical safety), EN 71-3 (child safety), and ASTM F2057 (slip resistance). For hospitality or kids’ spaces, these standards are critical.

5. What is the installation guideline for a fake sheepskin rug in commercial spaces?

Ensure floor is dry and dust-free. For high-traffic zones, select anti-slip TPR backing. Edges should abut walls or be layered under furniture to minimize movement. Some clients use optional double-sided tape.

6. Are these rugs suitable for machine washing? What cycle/temperature?

Most premium faux fur rugs (our model incl.) are machine washable on gentle cycle ≤30℃, low rpm (

7. What is the standard lead time and delivery for wholesale orders?

For faux fur rugs wholesale custom orders, production cycles span 10–18 days (standard), with express logistics via sea, rail, or air as per client location.

After-Sales Support, Delivery, and Warranty Details

- Quality Guarantee: 3-year “Total Care” warranty for manufacturing/defect issues.

- Order Support: End-to-end support including video QC, sample shipping, and 24/7 English and Chinese service.

- Delivery: 10–18 business days for custom lots (MOQ 25+ units), with tracked insurance shipment to 40+ global regions.

- Claims & Returns: Simple replacement for verified defects, color/size discrepancy per contract terms.

- Technical Consultation: Full pre- and post-sale technical consultancy for material selection, compliance, and after-care.

- Authenticity: All products batch tracked, ISO/ANSI-compliant with digital inspection reports.

References & Industry Resources

- Grand View Research, Faux Fur Market Size, Share & Trends Analysis Report, https://www.grandviewresearch.com/industry-analysis/faux-fur-market-report

- Textile Exchange, 2023 Preferred Fiber & Materials Market Report, https://textileexchange.org

- ISO 12945-2:2020 Textiles — Determination of fabric propensity to surface fuzzing and to pilling, https://www.iso.org/standard/73347.html

- Textile Learner professional forum discussion, “Latest Innovations in Faux Fur Manufacturing”, https://textilelearner.net/faux-fur-manufacturing-process/

Prev This is the first article

Products

Variety

Softness

Durability

Maintenance

Address

Floor 724 ,Building 7, No. 10, Tatan International Trade City, 118 Shengli South Street, Qiaoxi District, Shijiazhuang City, Hebei Province

Business Hours

Mon to Saturday : 8:00 am - 7:00 pm

Sunday & Holidays : Closed